Seal Tape Wrapping Machine Saves Time and Labor Costs

GSTAR-1 Seal Tape Wrapping Machine

【UNITIDE】Four

characteristics of Seal Tape Wrapping Machine:

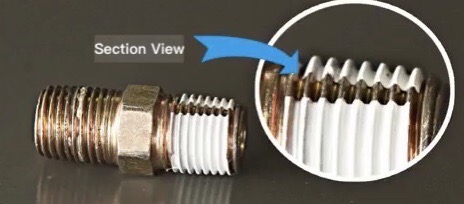

1. Tight winding of high-density PTFE tape.

Tape is wound tightly onto the threads to achieve a better, completely airtight, anti-leak seal.

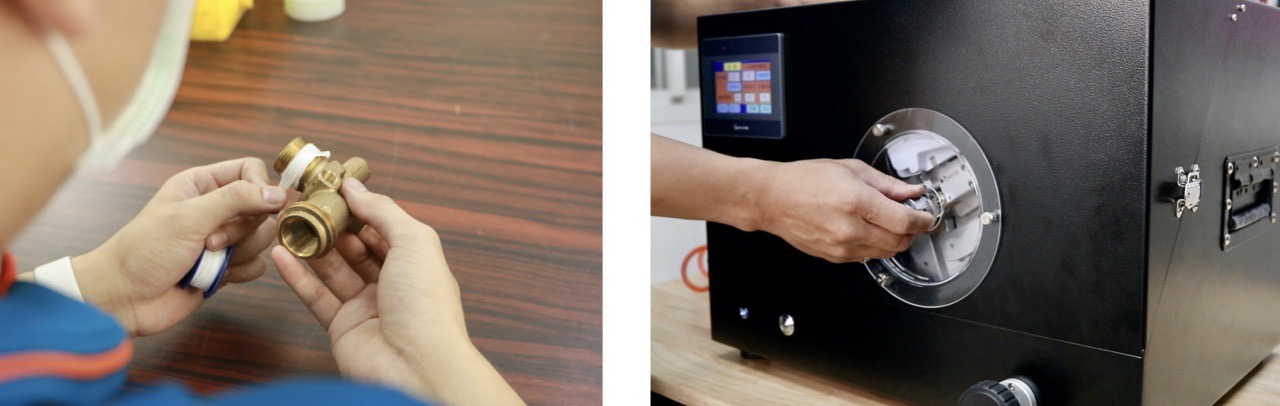

2. The user-machine interface is easy to operate.

Stand-alone operation. The speed and number of rotations can be adjusted according to requirements. Can be set to automatic mode, or manual mode, to adjust for fittings and fixtures.

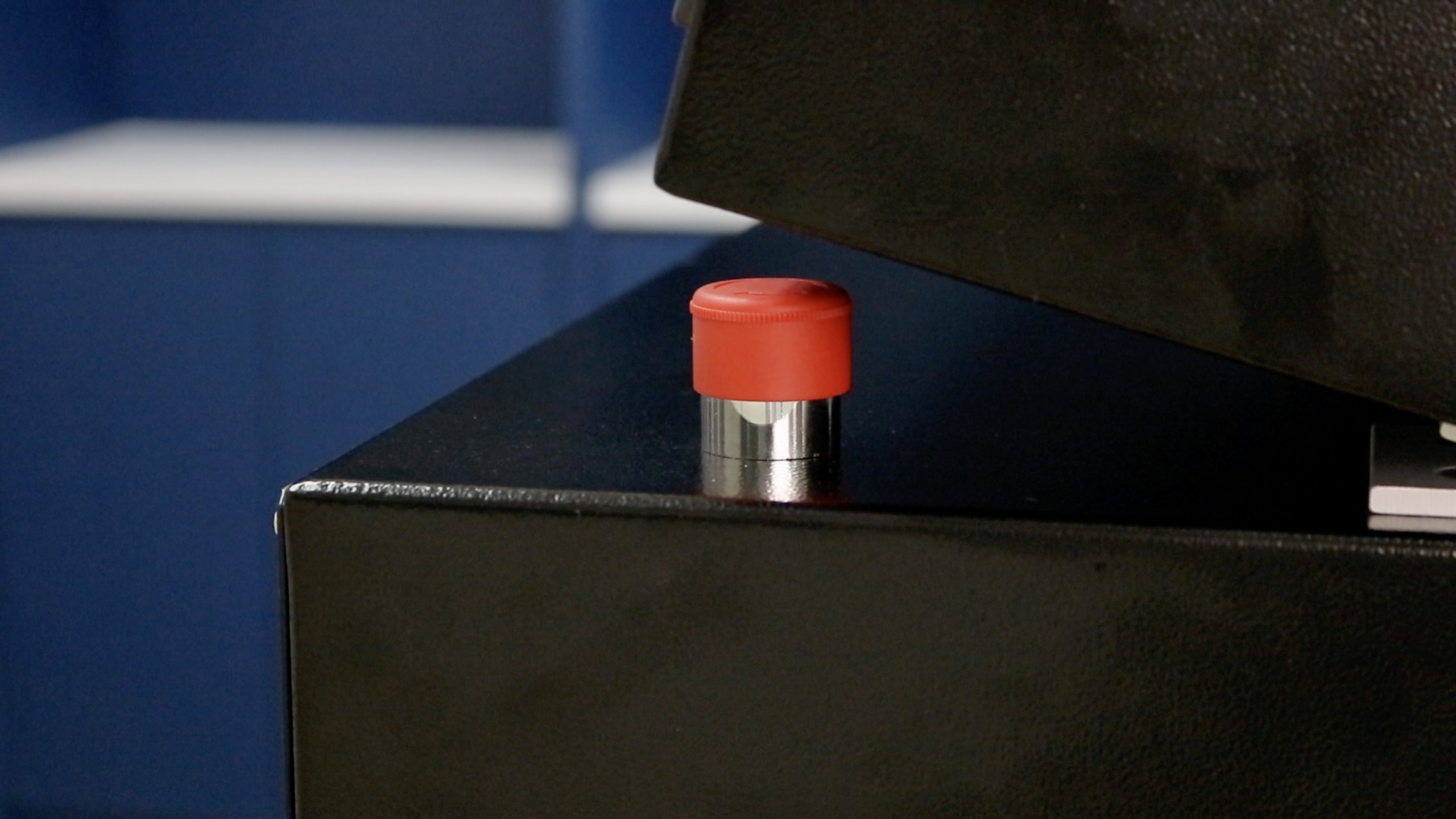

3. High safety.

Running stop while the front cover is opened, and dual safety switches : micro switch design, 2nd safety method - emergency stop switch.

4. Suitable for workpieces of various materials/sizes.

Equipped with variable tape sizes: 5mm, 7mm, 10mm, 13mm. Suitable for gas valves, oil pressure gauges, fire sprinklers, oil pressure fittings etc. Metal or plastic materials are all suitable for winding.

Do you think it is a simple process to wind sealing tape?

It seems simple to wind sealing tape, but incorrect winding, such as winding in

the wrong direction, applying an incorrect size of tape to the workpiece, or

incorrect number of turns will cause serious consequences.

For example, if the

connection is not properly tightened, it will cause an unstable joint. Oil

leakage, air leakage, and water leakage can all cause environmental problems.

Attention should be paid to the tape winding process.

The time cost spent on winding is often ignored. Why not improve work

efficiency?

We often look around for where we last set that small roll of sealing tape, and throw the roll away when it's used up. High skilled labor isn’t cheap. Forgetting the number of turns when winding, or not tightening properly can lead to quality problems that can have high hidden costs.

The above problems can be solved by Seal Tape Wrapping Machine!

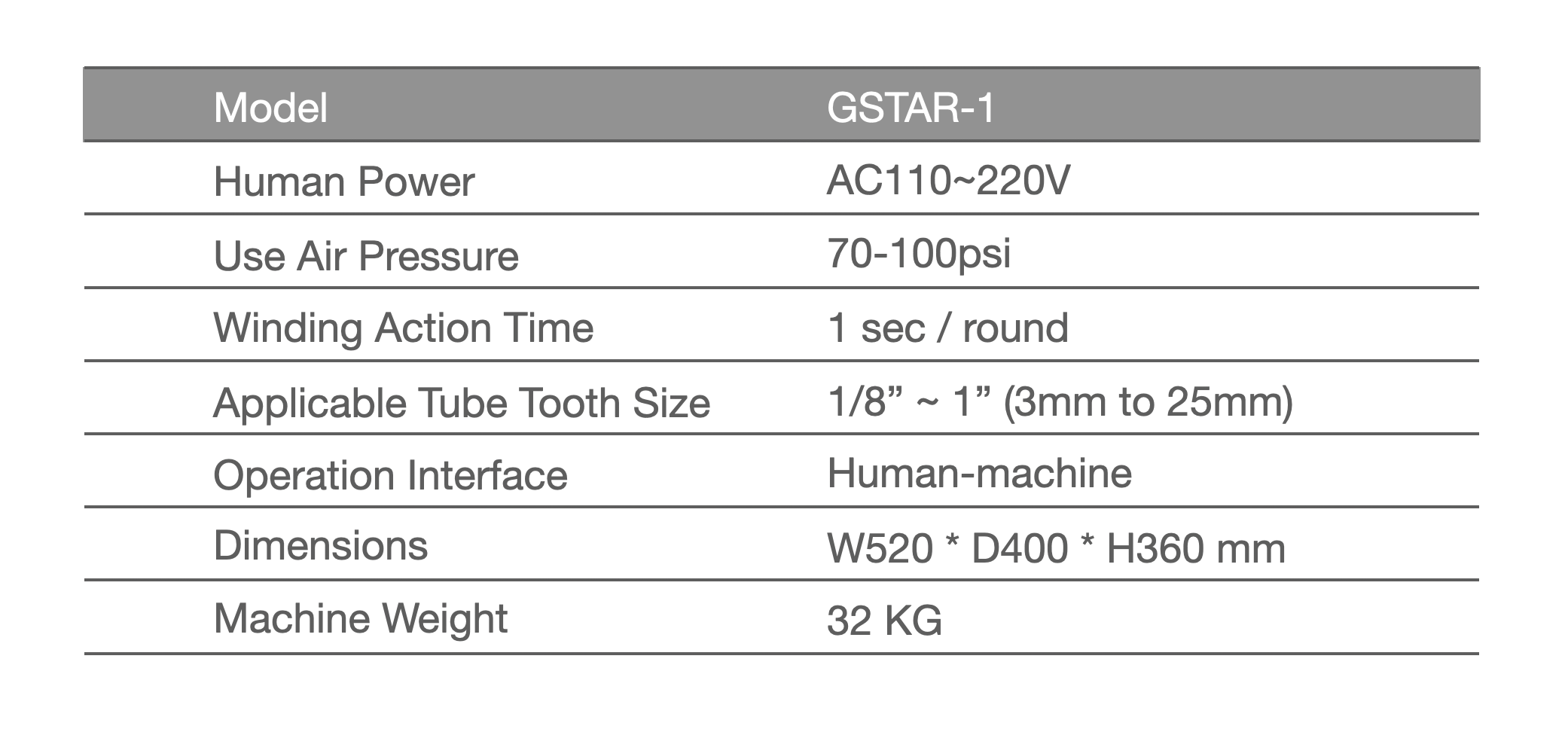

(Picture) Seal Tape Wrapping Machine / Machine specifications

Unitide, your needs, we care!