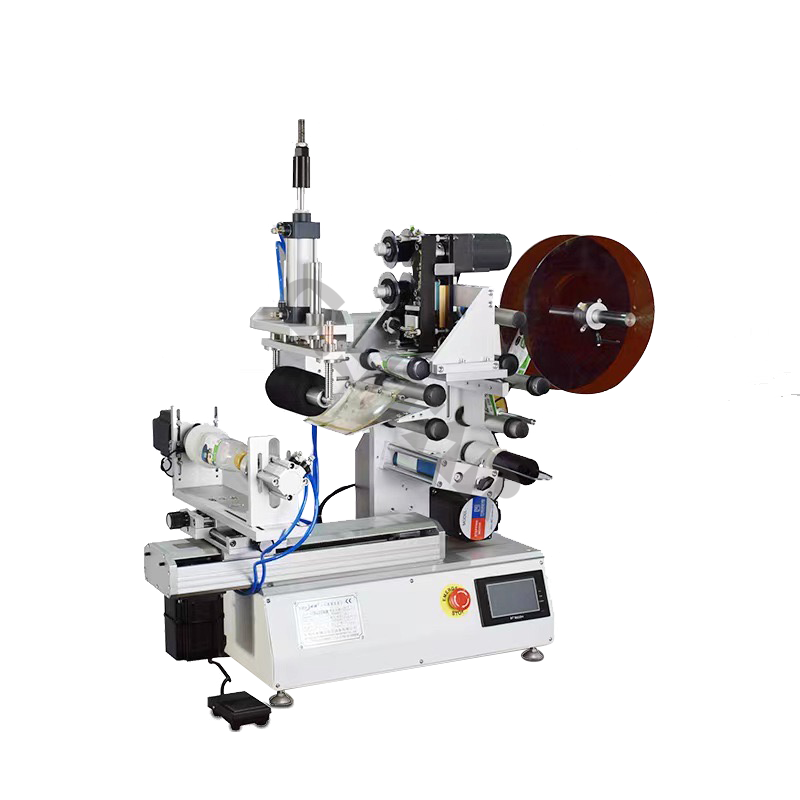

Desktop Multi-function Labeling Machine

‧Widely applicable for round bottles made of glass,plastic PP, PET and others as well as symmetrical and some irregular shaped products to stick self-adhesive labels or films; also applicable for double-sided adhesive products with die-cuttng.

‧It can be optionally integrated with "Clear Sticker Labeling Machine with Transparent Electric Eye Recognition" and "Coding Machine" for labeling and coding within one process.

‧Manual Feeding → Clamping → Labeling → Finished Product Output

‧It can be optionally integrated with "Clear Sticker Labeling Machine with Transparent Electric Eye Recognition" and "Coding Machine" for labeling and coding within one process.

‧Manual Feeding → Clamping → Labeling → Finished Product Output

Model :

GS-615

| GS-615 | |

| Machine Dimensions | L998 x W577 x H937 mm |

| Power Supply | 220V 60Hz, Power 0.5KW |

| Pneumatic Pressure | Min. 5KG |

| Machine Net Weight | 67.5KG |

| Production Capacity | 900-2400 Can/HR |

| Labeling Error | ±0.5 mm |

| Applicable Products | Diameter of Round Bottle:15-100 mm |

| Length:60-300 mm | |

| Dimension of Applicable Labels | Label Width (Height):5-180 mm |

| Length:5-350 mm |

| Wide application range: various shaped bottles like round, square, octagonal, flat, etc. (replacing fixtures required) |

| Easy to operate: switch to corresponding parameters when switching different products |

| Parameter memory: multiple parameter settings for various labels without setting parameters repeatedly |

| Production counting: with required labeling quantity set, the production will stop automatically when it is completed |

| High efficiency, manpower reduction, perfect labeling with high precision |

| Lower cost without wear parts |