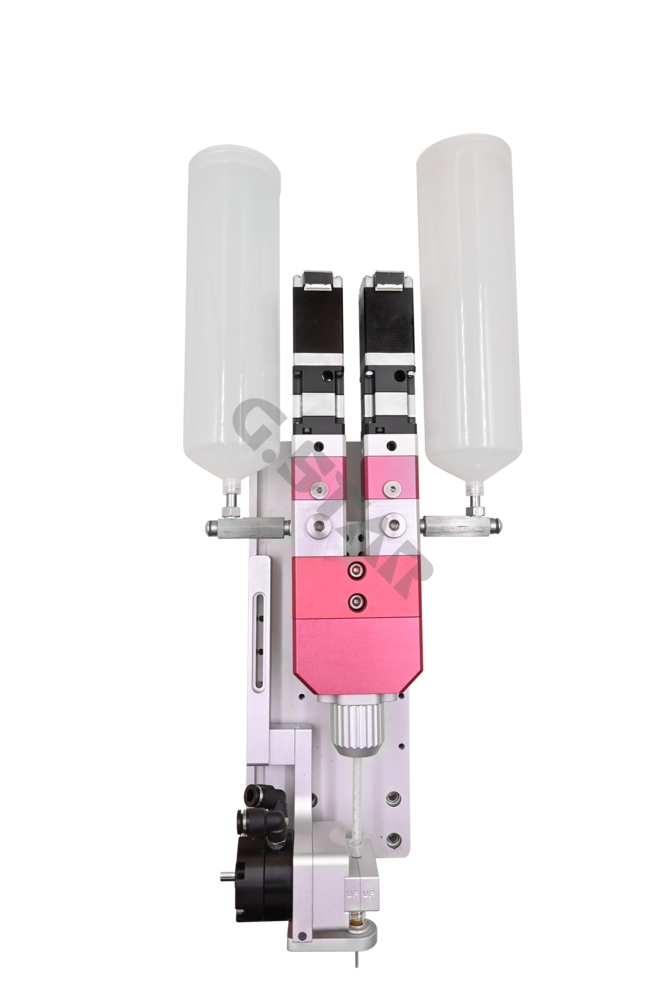

Dual fluid dispensing valve (precise micro-dosing)

Model :

GS-DU28004-SQ

| By combining different or identical single fluid machine valves, different dispensing volumes and mixing ratios are provided. |

| Precise dispensing volumes are generated through the mechanism design of rotor and stator. |

| By adjusting the main/hardener through the controller, different ratio mixing dispensing can be easily achieved with motor speed control. |

| Precise and stable dispensing without pulsation, quick stoppage without dripping through back suction function. |

| Suitable for adhesive viscosities up to 5,000,000cps. |

| Combined with the "Simple Dispenser" to allow the installation of mixing tube needles for more precise and stable dispensing. |

| Error ≦±1%, repeatability ≧99% (tested with water, at least 2 revolutions of main/hardener dispensing) |

| Troubleshooting | ||||

| 1. When the viscosity of the adhesive used with a single fluid machine valve is greater than 5,000cps and the inner diameter of the needle is less than 0.7 mm. | ||||

|

||||

|

||||

|

||||

| 2. Dual fluid machine valves must be installed with or without needles before the mixing tube: | ||||

|

||||

|

||||

|

||||

| Advantages of adding the "Simple Dispenser": | ||||

| 1. No need for back suction, immediate stoppage without dripping. | ||||

| 2. More stable dispensing volume, better dispensing repeatability. | ||||

| 3. Shorter waiting time at the starting point during line drawing, maintaining consistent line diameter from start to finish. | ||||

| 4. Disposable accessories, no cleaning issues. | ||||

| 5. Modular design, compatible with single fluid, dual fluid, or dynamic mixing of dual fluid. | ||||

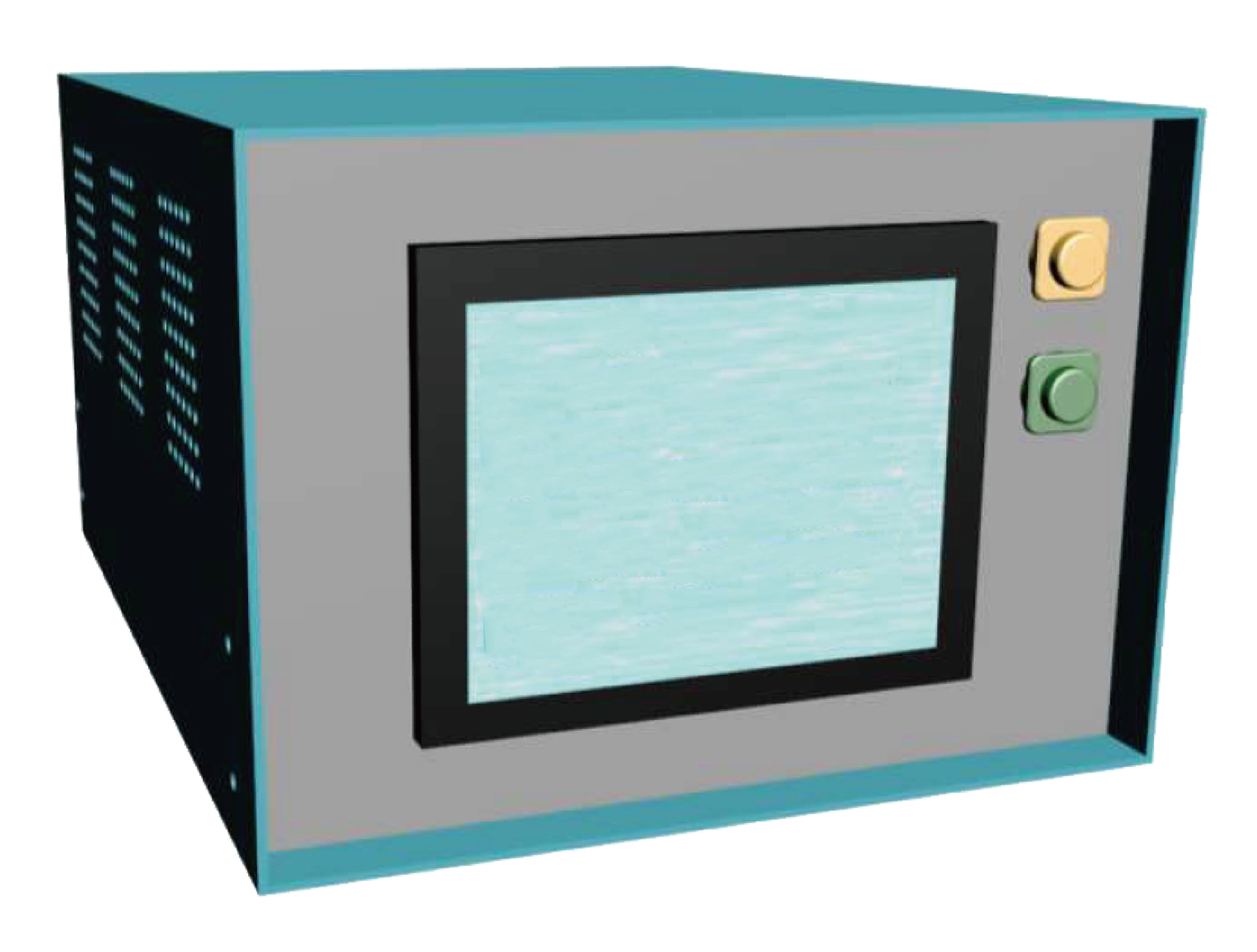

| Controller | ||||

| 1. Integrated, no need for an additional controller. | ||||

2. Integrated operation interface screen for convenience.

| HMI Touchscreen | |||

| Front buttons | |||

|

|||

|

|||

| Back buttons | |||

|

|||

|

|||

|

|||